I honestly couldn’t believe my luck ….. dozens of perfectly normal starts after the one stuck-solenoid moment during our 10 days away and then, this morning in the comfort of the old barn, first start of the day it stuck again!

I honestly couldn’t believe my luck ….. dozens of perfectly normal starts after the one stuck-solenoid moment during our 10 days away and then, this morning in the comfort of the old barn, first start of the day it stuck again!

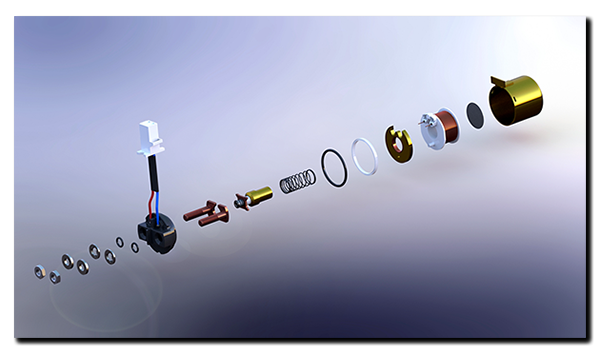

So it was off with the seats, top deck and right hand plastics, disconnect the battery Earth (Ground) then snip a few tie-wraps, unclip the two-pin connector and twiddle the 10mm spanner to undo the battery/starter cables from the old solenoid and voila! One dodgy 50A and 14 year old solenoid confined to the bin …… by way of stripping, measuring and knocking up in CAD!

It’s pretty obvious from the picture that one side of the contacts has been burnt and welded together such that the return spring couldn’t provide enough force to pry it apart again – that was the job of a swift whack from the all-powerful 1/2″ ratchet!

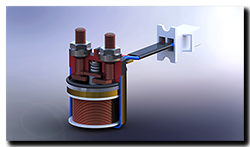

The new solenoid (AP81129275) was bench tested and shows a coil resistance of 4.4Ω pulling 2.9A at 12.8V – approximately! Now 2.9A is quite a current draw in itself, especially when you take into account the amount of wiring (under specified?) and switches/diodes along the way. The only way the solenoid really has of reducing pitting/burning is by opening and closing as fast as possible – opening is purely by return spring but the closing speed is proportional to the applied Volts/Amps ……. and if this is low then the solenoid will become sluggish and more susceptible to damage. So tomorrows little job will be to look at losses through the entire circuit up to the solenoid. In fact looking at the circuit diagram and simulating it in ‘EveryCircuit’ (Android app) it seems that the best possible current flow path you can give the solenoid is – bike in neutral, side-stand up AND pull in the clutch before hitting the starter … this adds a mighty 0.1V over ‘neutral only’. In comparison bypassing the diode block completely could elicit another 0.55V at a struggle!

The new solenoid (AP81129275) was bench tested and shows a coil resistance of 4.4Ω pulling 2.9A at 12.8V – approximately! Now 2.9A is quite a current draw in itself, especially when you take into account the amount of wiring (under specified?) and switches/diodes along the way. The only way the solenoid really has of reducing pitting/burning is by opening and closing as fast as possible – opening is purely by return spring but the closing speed is proportional to the applied Volts/Amps ……. and if this is low then the solenoid will become sluggish and more susceptible to damage. So tomorrows little job will be to look at losses through the entire circuit up to the solenoid. In fact looking at the circuit diagram and simulating it in ‘EveryCircuit’ (Android app) it seems that the best possible current flow path you can give the solenoid is – bike in neutral, side-stand up AND pull in the clutch before hitting the starter … this adds a mighty 0.1V over ‘neutral only’. In comparison bypassing the diode block completely could elicit another 0.55V at a struggle!

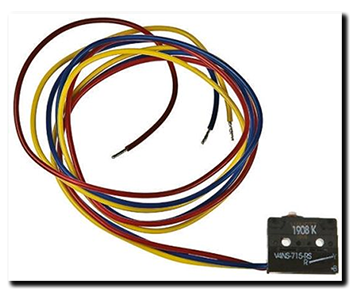

Just found out that the the Capo didn’t want to start in gear with the clutch pulled in …. so suspected a bad clutch switch. In the end it wasn’t, but I’d pulled the old one and did some homework anyway. The switch is a Saia Burgess V4NCS with an

Just found out that the the Capo didn’t want to start in gear with the clutch pulled in …. so suspected a bad clutch switch. In the end it wasn’t, but I’d pulled the old one and did some homework anyway. The switch is a Saia Burgess V4NCS with an  sheath/splice the other two. A darn sight less than the £70 plus that I’ve seen on the web for an Aprilia item! The only down-side appears to be that the cables exit from the side not the rear ….. no biggie really.

sheath/splice the other two. A darn sight less than the £70 plus that I’ve seen on the web for an Aprilia item! The only down-side appears to be that the cables exit from the side not the rear ….. no biggie really. With a hot brew to the left and a warm mouse to the right, I’m ready to reflect on the last ten days as the Capo sits outside soaking up the morning Abruzzo sun. After the hiccup at 138 miles the remainder of the 3,000 miles went perfectly, not one low-volt drama in sight. Mind you, that is with a new

With a hot brew to the left and a warm mouse to the right, I’m ready to reflect on the last ten days as the Capo sits outside soaking up the morning Abruzzo sun. After the hiccup at 138 miles the remainder of the 3,000 miles went perfectly, not one low-volt drama in sight. Mind you, that is with a new