Sorting the rear tensioner yesterday took all of 20 minutes, but I knew that the front was going to be a different kettle of fish altogether because of the coolant pipes. No worries, I thought – a good excuse to change out the coolant as well.

Sorting the rear tensioner yesterday took all of 20 minutes, but I knew that the front was going to be a different kettle of fish altogether because of the coolant pipes. No worries, I thought – a good excuse to change out the coolant as well.

So in I went and oh what fun it was! Off with the crash bars, side panels and sump guard, move the coolant bottle and release the radiator bottom hose and drain the system – so far, so good. Remove the airbox and release the clamps holding the throttle bodies in the inlet rubbers ….. hmmmm – looks like they’ve got a few deep cracks I’m thinking.

Take off the rest of the hoses, cables and electrical connectors, now a gentle pull and twist to release the throttle bodies and ……………… oops! I think the cracks in that rubber were a tad deeper than first thought and a touch beyond repairing with a splash of rubberised goo. Luckily I’ve a spare pair to hand from the l’Aquila stash. However, this momentry inconvenience isn’t the task of the day ….. so onward once more. Hoses, cables anything and everything moved so I could at last get to the two clamps holding the ‘Y’ hose in place – then finally the goal was in sight, the pot at the end of the rainbow …. the front cam chain tensioner!

Take off the rest of the hoses, cables and electrical connectors, now a gentle pull and twist to release the throttle bodies and ……………… oops! I think the cracks in that rubber were a tad deeper than first thought and a touch beyond repairing with a splash of rubberised goo. Luckily I’ve a spare pair to hand from the l’Aquila stash. However, this momentry inconvenience isn’t the task of the day ….. so onward once more. Hoses, cables anything and everything moved so I could at last get to the two clamps holding the ‘Y’ hose in place – then finally the goal was in sight, the pot at the end of the rainbow …. the front cam chain tensioner!

With a heave, a grunt and too many fingers trying to get into too small a space I managed to retrieve the tensioner from its hide-away, gave it a squeeze and ……… it was fine, solid as a rock! Never mind, a flush to clean out any debris and a refill with clean oil never hurt.

With a heave, a grunt and too many fingers trying to get into too small a space I managed to retrieve the tensioner from its hide-away, gave it a squeeze and ……… it was fine, solid as a rock! Never mind, a flush to clean out any debris and a refill with clean oil never hurt.

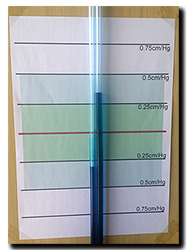

Then it was rebuild time. The tensioner’s in place and the cap torqued down to 30Nm with a swanky new copper washer. The super-shiny inlet rubbers torque down at 19Nm and the rest of course is then a reversal of strip-down – with the intention of NOT ending up with any washers, screws or clips left over! And so with the sun ready to slip behind the mountains it was test-time. Glad to say she fired up first hit of the button and sounded so much smoother, funny how you get used to little noises and ‘character’ over time – now she’s idling smooth as can be, a tweak on the throttle body sync screw had the manometer within a couple of mills AND it stayed that way when the motor was reved, something it didn’t do last week. So I’m guessing the cracked inlet rubbers were an issue after all! 😳 So that’s it for today, other than updating the Capo’s history spreadsheet ….. the Capo has now done a pinch over 74,400 miles and other than a couple of valve shims and plugs, it’s the only work the motor has ever needed.

Next stop – tyres, chain and sprockets. 😯

It’s been a while since the Capo was serviced and one job has still remained outstanding – in fact it has been ‘outstandingly’ outstanding for the past few services since I lost my old

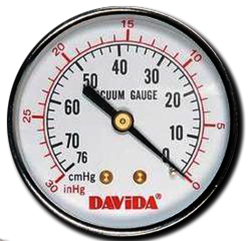

It’s been a while since the Capo was serviced and one job has still remained outstanding – in fact it has been ‘outstandingly’ outstanding for the past few services since I lost my old  First off, what kind of vacuum are we looking at from the Capo motor? From measurements, it looks to be somewhere in the range of 22-24cmHg (based on an erratic Carbtune II) per cylinder measured against atmospheric pressure …. Now that’s not much for a mercury manometer – barely the length of a sheet of A4 paper. A nice compact manometer then, except that unfortunately mercury is almost impossible to get hold of because it’s deemed way too dangerous for us potato-heads to use safely. So what does this mean in terms of manometer height if we use liquids of a lower density? Well…..

First off, what kind of vacuum are we looking at from the Capo motor? From measurements, it looks to be somewhere in the range of 22-24cmHg (based on an erratic Carbtune II) per cylinder measured against atmospheric pressure …. Now that’s not much for a mercury manometer – barely the length of a sheet of A4 paper. A nice compact manometer then, except that unfortunately mercury is almost impossible to get hold of because it’s deemed way too dangerous for us potato-heads to use safely. So what does this mean in terms of manometer height if we use liquids of a lower density? Well…..

In the flush of youth I was the same as most fledgling bikers I guess, spending endless hours cleaning my bike with mates over a cold beer and loud music ….. of course all that changed when riding a bike became a job five or six days a week. Washing the bike turned into a chore, something to be endured not enjoyed through endless ice-cold winter weeks, honed into a slick process to illicit the most benefit from the least input.

In the flush of youth I was the same as most fledgling bikers I guess, spending endless hours cleaning my bike with mates over a cold beer and loud music ….. of course all that changed when riding a bike became a job five or six days a week. Washing the bike turned into a chore, something to be endured not enjoyed through endless ice-cold winter weeks, honed into a slick process to illicit the most benefit from the least input.

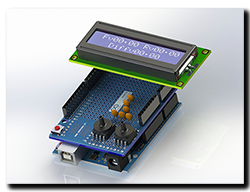

Stop the Bus (or your Caponord) and grab yer smartphones again, TuneECU has just been updated to V2.2 ………… worthy of mentioning? Oh Yes! Alaine has addressed the poor connection (cable) AND the screen freezing if you swiped it when logging issue. Now TuneECU connects to the Capo quick as you like, just as it used to. I tried it numerous times and never once had a problem – fantastic! All-in-all a positive step forward …..

Stop the Bus (or your Caponord) and grab yer smartphones again, TuneECU has just been updated to V2.2 ………… worthy of mentioning? Oh Yes! Alaine has addressed the poor connection (cable) AND the screen freezing if you swiped it when logging issue. Now TuneECU connects to the Capo quick as you like, just as it used to. I tried it numerous times and never once had a problem – fantastic! All-in-all a positive step forward ….. While the weather’s been holding up, I decided to wheel the Capo out and give it a wash. As I soaped, sponged and lathered my way down the left hand side something caught my eye and a hollow feeling opened up in the pit of my stomach ……. something broken or rusty? No, worse – the bloody (road) tax needed renewing!

While the weather’s been holding up, I decided to wheel the Capo out and give it a wash. As I soaped, sponged and lathered my way down the left hand side something caught my eye and a hollow feeling opened up in the pit of my stomach ……. something broken or rusty? No, worse – the bloody (road) tax needed renewing!

Connection was the same as before and data is still slow to update – tacho and TPS seem quick enough but the side-stand takes a whopping 5 seconds to change state. Still no side-stand or Fan status indicator like the PC version. The datalog facility worked, but seems to have a bug, more on this later.

Connection was the same as before and data is still slow to update – tacho and TPS seem quick enough but the side-stand takes a whopping 5 seconds to change state. Still no side-stand or Fan status indicator like the PC version. The datalog facility worked, but seems to have a bug, more on this later.

What good is a motorbike or a car for that matter, if you don’t have a road to run along?

What good is a motorbike or a car for that matter, if you don’t have a road to run along?

A quick

A quick

accommodate the twin indicator repeaters has had no impact, positive or negative. The voltmeter has been a different kettle of fish …. generally unused as the

accommodate the twin indicator repeaters has had no impact, positive or negative. The voltmeter has been a different kettle of fish …. generally unused as the  The second anniversary, although shorter at 6 months and a tad over 11K miles, is the

The second anniversary, although shorter at 6 months and a tad over 11K miles, is the