Yesterday was a great day, warm and a smooth running Capo to zip about on …… not so today, no siree Bob. Started her up this morning and that dreaded little EFI light started flashing away. Front coil #1 (code 33) had shuffled off to the great coil playground in the sky.

Yesterday was a great day, warm and a smooth running Capo to zip about on …… not so today, no siree Bob. Started her up this morning and that dreaded little EFI light started flashing away. Front coil #1 (code 33) had shuffled off to the great coil playground in the sky.

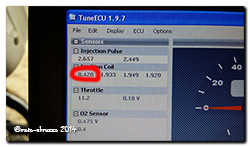

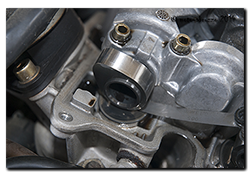

Before swapping it out, I plugged TuneECU in to get a screenshot of the dwell – reading 0.420 in the picture – definitely dead as a Dodo. Not to worry though, a spare was on the  shelf and an hour later the job was well and truly jobbed. Just two things to mention really ….. one, changing that rubber sleeve is a right pain in the proverbial and two, getting the HT lead onto the Amrish coils is even harder! Note to self …. make sure the next spare coil on the shelf is already fitted into a sleeve and has a HT lead attached, that’ll save at least 15 minutes and a book full of swear words! So after 92,413Km the second Sagem coil has been replaced, the first went a couple of years ago, so will the last two make it to the big 100K Km?

shelf and an hour later the job was well and truly jobbed. Just two things to mention really ….. one, changing that rubber sleeve is a right pain in the proverbial and two, getting the HT lead onto the Amrish coils is even harder! Note to self …. make sure the next spare coil on the shelf is already fitted into a sleeve and has a HT lead attached, that’ll save at least 15 minutes and a book full of swear words! So after 92,413Km the second Sagem coil has been replaced, the first went a couple of years ago, so will the last two make it to the big 100K Km?

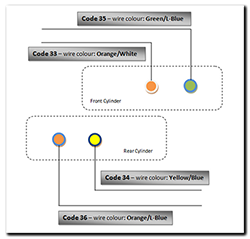

Here’s a graphic I keep (laminated) on top of the airbox lid – it just makes it easier to locate the right coil without consulting the manuals. Click for a bigger version.

so once I’d had a play I never touched it again – especially in the rain soaked confines of the UK.

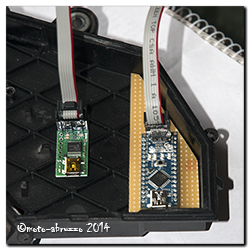

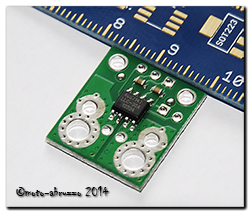

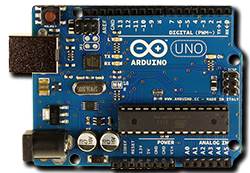

so once I’d had a play I never touched it again – especially in the rain soaked confines of the UK. And that brings me up to date I guess. 2014, a new year and all that jazz, will see moto-abruzzo once again playing with video. Hopefully this time it will add a new perspective to the website and move things in a slightly different direction. After a few weeks of internet-homework, weighing up the pros and cons of some amazing kit, I’ve chosen the

And that brings me up to date I guess. 2014, a new year and all that jazz, will see moto-abruzzo once again playing with video. Hopefully this time it will add a new perspective to the website and move things in a slightly different direction. After a few weeks of internet-homework, weighing up the pros and cons of some amazing kit, I’ve chosen the

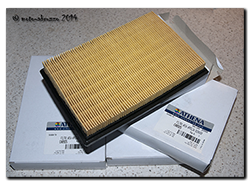

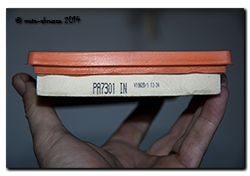

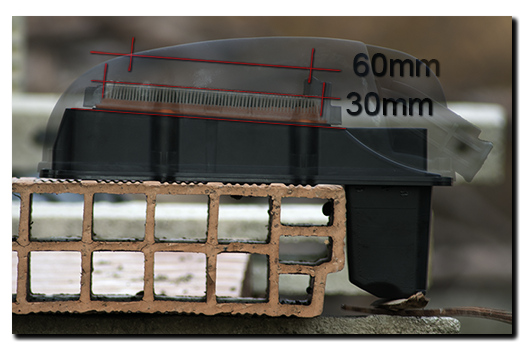

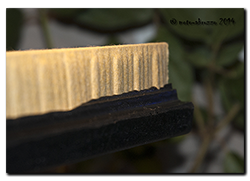

The vertical lines show where the filter ends or interferes with the frame or lid. As you can see, the 60mm high PA7180 will squash in at the ends …… will this be enough to restrict air

The vertical lines show where the filter ends or interferes with the frame or lid. As you can see, the 60mm high PA7180 will squash in at the ends …… will this be enough to restrict air

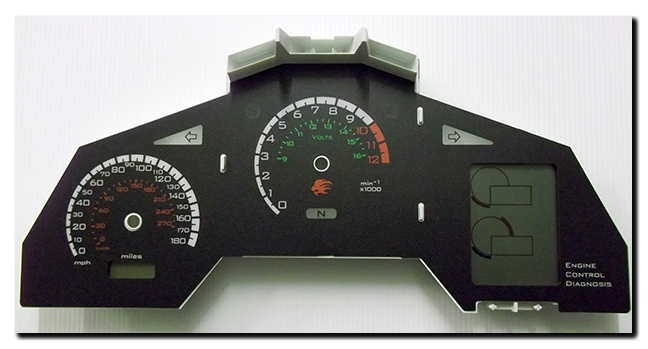

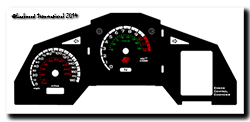

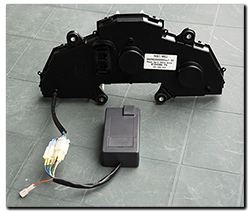

As well as getting the inlay reprinted with the added voltmeter graphic, I’ve also decided on a little re-arrangement of the existing graphics and functions. For example, why oh why is a ‘side-stand’ light prime-center of the display when it already has a safety circuit to stop you riding away with the stand down? ….. Magneti Marelli over-egging the pudding I think.

As well as getting the inlay reprinted with the added voltmeter graphic, I’ve also decided on a little re-arrangement of the existing graphics and functions. For example, why oh why is a ‘side-stand’ light prime-center of the display when it already has a safety circuit to stop you riding away with the stand down? ….. Magneti Marelli over-egging the pudding I think.