Sorting the rear tensioner yesterday took all of 20 minutes, but I knew that the front was going to be a different kettle of fish altogether because of the coolant pipes. No worries, I thought – a good excuse to change out the coolant as well.

Sorting the rear tensioner yesterday took all of 20 minutes, but I knew that the front was going to be a different kettle of fish altogether because of the coolant pipes. No worries, I thought – a good excuse to change out the coolant as well.

So in I went and oh what fun it was! Off with the crash bars, side panels and sump guard, move the coolant bottle and release the radiator bottom hose and drain the system – so far, so good. Remove the airbox and release the clamps holding the throttle bodies in the inlet rubbers ….. hmmmm – looks like they’ve got a few deep cracks I’m thinking.

Take off the rest of the hoses, cables and electrical connectors, now a gentle pull and twist to release the throttle bodies and ……………… oops! I think the cracks in that rubber were a tad deeper than first thought and a touch beyond repairing with a splash of rubberised goo. Luckily I’ve a spare pair to hand from the l’Aquila stash. However, this momentry inconvenience isn’t the task of the day ….. so onward once more. Hoses, cables anything and everything moved so I could at last get to the two clamps holding the ‘Y’ hose in place – then finally the goal was in sight, the pot at the end of the rainbow …. the front cam chain tensioner!

Take off the rest of the hoses, cables and electrical connectors, now a gentle pull and twist to release the throttle bodies and ……………… oops! I think the cracks in that rubber were a tad deeper than first thought and a touch beyond repairing with a splash of rubberised goo. Luckily I’ve a spare pair to hand from the l’Aquila stash. However, this momentry inconvenience isn’t the task of the day ….. so onward once more. Hoses, cables anything and everything moved so I could at last get to the two clamps holding the ‘Y’ hose in place – then finally the goal was in sight, the pot at the end of the rainbow …. the front cam chain tensioner!

With a heave, a grunt and too many fingers trying to get into too small a space I managed to retrieve the tensioner from its hide-away, gave it a squeeze and ……… it was fine, solid as a rock! Never mind, a flush to clean out any debris and a refill with clean oil never hurt.

With a heave, a grunt and too many fingers trying to get into too small a space I managed to retrieve the tensioner from its hide-away, gave it a squeeze and ……… it was fine, solid as a rock! Never mind, a flush to clean out any debris and a refill with clean oil never hurt.

Then it was rebuild time. The tensioner’s in place and the cap torqued down to 30Nm with a swanky new copper washer. The super-shiny inlet rubbers torque down at 19Nm and the rest of course is then a reversal of strip-down – with the intention of NOT ending up with any washers, screws or clips left over! And so with the sun ready to slip behind the mountains it was test-time. Glad to say she fired up first hit of the button and sounded so much smoother, funny how you get used to little noises and ‘character’ over time – now she’s idling smooth as can be, a tweak on the throttle body sync screw had the manometer within a couple of mills AND it stayed that way when the motor was reved, something it didn’t do last week. So I’m guessing the cracked inlet rubbers were an issue after all! 😳 So that’s it for today, other than updating the Capo’s history spreadsheet ….. the Capo has now done a pinch over 74,400 miles and other than a couple of valve shims and plugs, it’s the only work the motor has ever needed.

Next stop – tyres, chain and sprockets. 😯

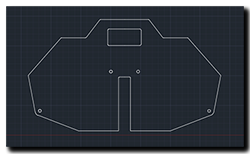

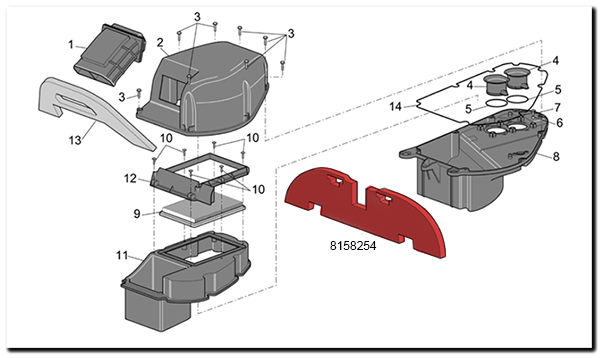

I finally got around to finishing off the new closure panel (AP8168916) and seat/tank heatshield (AP8117201 – now unavailable) using the 2mm rubber sheet I bought a few months ago. A single 500mm x 500mm piece is enough to make one each of the panels at a cost of about £4 per panel. Compare that to the list price of Aprilia replacements – £15.58 & £22.48 each PLUS VAT!

I finally got around to finishing off the new closure panel (AP8168916) and seat/tank heatshield (AP8117201 – now unavailable) using the 2mm rubber sheet I bought a few months ago. A single 500mm x 500mm piece is enough to make one each of the panels at a cost of about £4 per panel. Compare that to the list price of Aprilia replacements – £15.58 & £22.48 each PLUS VAT!

Last year the tester at the MOT station didn’t like the slightly low headlight beams (set to offset loaded panniers) and wanted to raise them. Unfortunately I think he raised the left-hand to the point of possibly unseating the ball at the end of the adjuster screw from the reflector. Friction alone on the other pivots probably only holding it in place to his satisfaction. About a month ago the same headlight went out of vertical alignment a little, then finally the other evening, suddenly dropped completely (and very noticeably!) so the low-beam was now tripping over the front wheel!

Last year the tester at the MOT station didn’t like the slightly low headlight beams (set to offset loaded panniers) and wanted to raise them. Unfortunately I think he raised the left-hand to the point of possibly unseating the ball at the end of the adjuster screw from the reflector. Friction alone on the other pivots probably only holding it in place to his satisfaction. About a month ago the same headlight went out of vertical alignment a little, then finally the other evening, suddenly dropped completely (and very noticeably!) so the low-beam was now tripping over the front wheel!